OLED Displays in Consumer Tech The Good and the Bad

If you want a screen with bright colors and deep blacks, you might pick an oled display. OLED displays are special because they use less energy, have better contrast, and are thin and light. You can see the screen well from many angles, so it looks good almost anywhere. But oled displays also have some problems. They cost more money, and they do not last as long as LCDs. You might see burn-in or damage if you use your oled in hot or wet places. Here is a quick look at the good and bad sides:

|

Advantages |

Disadvantages |

|---|---|

|

Uses less energy |

Does not last as long |

|

Thin and light |

Costs more money |

|

Better contrast and wide angles |

Can get hurt by heat or wet places |

Key Takeaways

-

OLED displays show great picture quality. They have deep blacks and bright colors. This makes them good for movies and games. These screens use less energy with dark images. This helps devices last longer on battery. OLED technology lets screens be thin and bendable. This helps make cool products like foldable phones and curved TVs. Watch out for burn-in problems. Do not leave the same image on the screen for too long. This keeps the display looking good. Think about your budget. OLED displays usually cost more than LCDs. They may not last as long either.

What Is OLED Display Technology

How OLED Displays Work

You might ask why an oled screen is not like other screens. OLED means "organic light-emitting diode." This means the screen uses special organic stuff that glows when electricity goes through it. Each pixel in an oled makes its own light. So, you do not need a backlight like LCD screens do.

Here’s an easy way to see how an oled works:

|

Component |

Function |

|---|---|

|

Substrate |

The bottom layer, made of plastic, glass, or metal foil. |

|

Anode |

Sends positive charges into the organic layers. |

|

Hole Injection Layer |

Helps move positive charges deeper into the device. |

|

Hole Transport Layer |

Carries those charges to the part that makes light. |

|

Emissive Layer |

This is where the light is made. |

|

Blocking Layer |

Keeps the light-making process working well by holding electrons in place. |

|

Electron Transport Layer |

Moves negative charges to the light-making layer. |

|

Cathode |

Sends negative charges into the organic layers. |

When you turn on your oled, electricity moves through these layers. Positive charges from the anode and negative charges from the cathode meet in the emissive layer. This meeting makes energy, and that energy turns into light. Scientists call this "electroluminescence." You see bright colors and deep blacks because each pixel makes its own light.

Unique Features of OLED

OLED displays are special for a few reasons. You get great picture quality with real blacks and bright colors. The screen can be very thin and even bendy. This means you might see oled in curved TVs or foldable phones. Here’s a quick comparison:

|

Feature |

OLED Displays |

LED Displays |

|---|---|---|

|

Picture Quality |

Better, with deep blacks |

Good, but not as deep |

|

Flexibility |

Can bend or curve |

Stays flat and stiff |

|

Response Time |

Very fast |

Slower |

|

Viewing Angles |

Looks good from almost any angle |

Can lose brightness at angles |

|

Heat Emission |

Stays cool |

Gets warmer |

|

Durability |

Can wear out faster |

Lasts longer |

|

Cost |

Usually more expensive |

More affordable |

You will see oled screens use less energy and stay cooler. They do not need a backlight. You also get smooth motion and clear pictures, even during fast scenes. These things make oled a top pick for people who want the best screen.

OLED Display Advantages

Picture Quality and Contrast

When you look at an OLED display, the picture looks great. The colors are bright, and the blacks look very dark. Each pixel can turn on or off by itself. This gives you true blacks and strong contrast. You can see details in dark scenes. Bright parts look even brighter.

-

OLED displays show perfect blacks because pixels can turn off.

-

You get very high contrast, so the picture stands out.

-

The colors look real and bright. You see many shades and tones.

-

OLED displays show better colors than most other screens.

-

The color accuracy is great, so the picture looks real.

A study tested OLED and LCD screens with black images. OLED screens gave off almost no light. LCD screens still glowed a little. This shows OLED displays have deeper blacks and better contrast. You get a lifelike picture, which is good for movies and games.

Energy Efficiency

You might wonder how OLED displays use battery power. One big benefit is they use less energy with dark images. OLED displays can turn off pixels to save power. If you use dark themes or watch movies with shadows, your battery lasts longer.

But if you use bright images or white backgrounds, OLED displays can use more power than LCDs. For example, a laptop with an OLED display might last six to seven hours with lots of white on the screen. An LCD could last ten to eleven hours. Still, most people like OLED displays because they save energy, especially with dark mode.

Thinness and Flexibility

OLED displays are not just good for pictures. They are also thin and bendy. You can find OLED screens in foldable phones, rollable TVs, and curved wearables. OLED displays do not need a backlight. This makes them lighter and easy to bend.

|

Feature |

Description |

|---|---|

|

Flexibility |

OLED displays can bend, fold, or roll without breaking. |

|

Design Freedom |

No backlight means more creative shapes and thinner devices. |

|

Curvature |

OLED panels can curve tightly, even as small as 1mm radius. |

You see OLED displays in new gadgets that can change shape or fold. This flexible design gives you more choices. Devices are easier to carry. You get a screen that fits your life, like a foldable phone or a curved smartwatch.

Viewing Angles

Have you ever looked at a screen from the side and seen colors fade? With OLED displays, you do not have that problem. OLED displays have wide viewing angles. You can sit almost anywhere and still see bright colors and a sharp picture.

|

Display Technology |

Viewing Angle Characteristics |

|---|---|

|

OLED |

Wide viewing angles with steady brightness and color accuracy |

|

LED and QLED |

Good, but colors and brightness can change at sharp angles |

OLED displays keep their picture quality even at wide angles, up to 170° × 170°. The colors stay the same, and the contrast stays strong. You get a great experience whether you sit in front or on the side. This makes OLED displays good for sharing videos or playing games with friends.

Tip: If you want the best picture quality, great color accuracy, and deep blacks, OLED displays are a great choice. You also get thin, bendy screens and wide viewing angles.

OLED Display Disadvantages

When you look at the bright side of an oled display, you see amazing colors and deep contrast. But you also need to think about the disadvantages. Every technology has its weak spots. Let’s talk about the main problems you might face with oled displays.

Burn-In Issues with OLED

Burn-in is one of the biggest disadvantages you’ll hear about with oled displays. Burn-in happens when you see a faded image or shadow on your screen that won’t go away. This problem shows up if you keep static images on your display for a long time. For example, if you leave a logo or a game score on your screen, those pixels work harder and wear out faster. You might notice burn-in after using your oled display for a couple of years.

-

About 5% of users see burn-in after two years of normal use.

-

If you use your oled display for digital signs or keep static images on the screen, burn-in can show up in just a few months.

You can lower your risk of burn-in by following some simple steps:

-

Change what’s on your screen often. Don’t leave static images for hours.

-

Turn down the brightness. High brightness makes burn-in worse.

-

Use dark mode or similar settings. This helps your pixels rest.

-

Try a white screensaver to refresh your display.

-

If you have an LG OLED TV, use the Pixel Refresher tool.

Tip: If you want your oled display to last longer, avoid leaving static images on the screen and keep your brightness low.

Lifespan and Durability

You might wonder how long your oled display will last. The lifespan is another disadvantage you should know about. Oled displays usually last between 8 and 13 years, depending on how you use them. That’s less than some LCD displays, but more than LED displays. Here’s a quick look:

|

Display Type |

Average Lifespan (Hours) |

Average Lifespan (Years) |

|---|---|---|

|

OLED |

30,000 - 100,000 |

8 - 13 |

|

LCD |

60,000 - 100,000 |

7 - 11 |

|

LED |

40,000 - 60,000 |

4.5 - 7 |

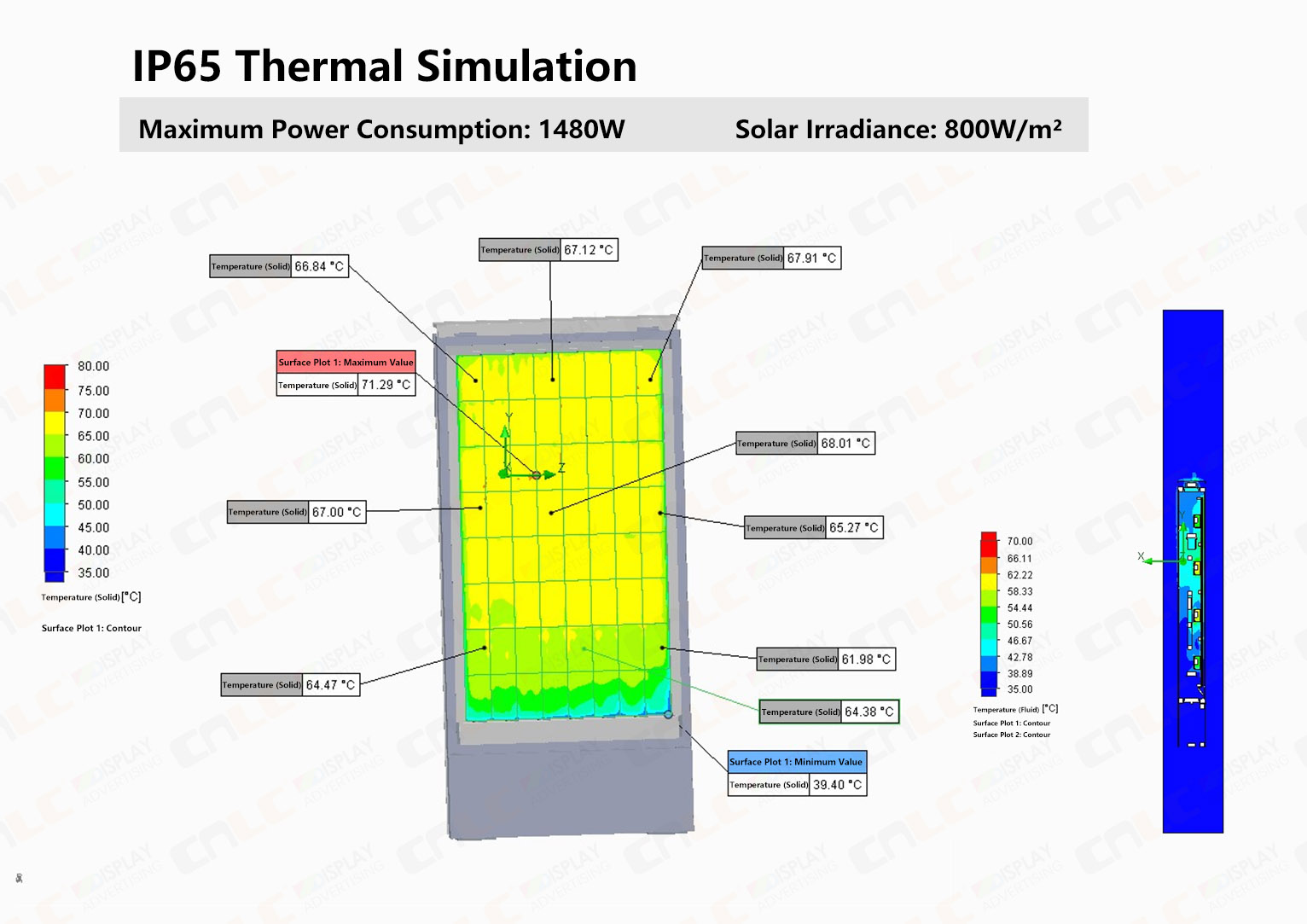

Oled displays can also get damaged by heat or humidity. High temperature makes your display lose brightness and can even cause colors to change. Humidity lets water get inside, which can break your display and lower its performance.

|

Environmental Factor |

Effect on OLED Displays |

|---|---|

|

High Temperature |

Makes your display fade, lose brightness, and even fail. |

|

High Humidity |

Lets water in, causes defects, and lowers performance. |

If you use your oled display in a hot or wet place, you might see problems sooner. So, keep your devices cool and dry.

Cost Considerations

Cost is a big disadvantage for many people thinking about oled displays. You pay more for the great contrast and colors. The price difference is easy to see when you compare oled displays to LCD or LED displays.

|

Device Type |

LCD Panel Cost |

OLED Panel Cost |

OLED Premium |

|---|---|---|---|

|

55" TV Panel |

~$230 |

~$582 |

2.5x |

|

5.7" Smartphone |

~$15.39 |

~$18.62 |

~20% |

|

5.8" Flexible OLED |

N/A |

~$22.61 |

N/A |

Oled displays cost more because they are harder to make. The process uses special organic materials and needs careful handling. You also pay more because oled displays don’t last as long, so you might need to replace them sooner. The price gap is getting smaller, but oled displays still cost more than LCD screens.

-

Oled displays are more expensive to produce than LCD screens.

-

The process is more complex and uses pricier materials.

-

Shorter lifespan means you might pay more over time.

If you want the best picture, you pay a higher cost. Think about your budget before you choose an oled display.

Brightness Limitations

Brightness is another disadvantage you should know about. Oled displays look great in most rooms, but they can struggle in very bright places. High-end LED monitors can get much brighter because they use strong backlights. If you use your device outside or in a sunny room, you might notice your oled display looks dim.

-

Oled displays have lower peak brightness than high-end LED monitors.

-

LED monitors work better in bright environments.

-

Brightness matters if you watch TV or play games in a sunny spot.

You get amazing contrast and colors with oled displays, but you might miss out on strong brightness. If you need a display for outdoor use or a room with lots of sunlight, think about this disadvantage before you buy.

Note: Oled displays give you deep contrast and vibrant colors, but you pay more and get less brightness in some situations. Always check your needs before you choose.

OLED vs. Other Display Technologies

OLED vs. LCD

You may wonder how oled displays compare to LCD screens. There are big differences in how they look and work. Oled displays can make perfect blacks. Each pixel turns off by itself. LCD screens use a backlight, so they cannot show true black. Colors on oled displays look brighter and more real. You also get better viewing angles. The picture stays clear even from the side.

Here’s a quick table to help you compare:

|

Feature |

OLED Displays |

LCD Displays |

|---|---|---|

|

Black Levels |

Exceptional, perfect blacks |

Limited, cannot achieve true blacks |

|

Contrast Ratios |

Nearly infinite contrast ratio |

Lower contrast ratios |

|

Viewing Angles |

Consistent and accurate colors |

Color shifting and decreased contrast |

|

Color Accuracy |

Wide color gamut, vibrant images |

Decent, but less accurate |

|

Burn-in |

Prone to burn-in over time |

More resistant to burn-in |

|

Lifespan |

Generally shorter lifespan |

Typically longer lifespan |

If you want the best picture for movies or games, oled displays are better. LCDs last longer and cost less. They are good for everyday use.

OLED vs. LED

You see LED displays in many places, like TVs and monitors. LED screens use a backlight. This means every pixel gets the same light. Oled displays light up each pixel on its own. You get deeper blacks and better contrast. When you look at energy use, LED displays usually use less power. This is true in bright scenes.

Here’s what you should know:

-

LED TVs use a backlight, so power use stays steady.

-

Oled displays change power use based on the picture. Dark scenes use less power. Bright scenes use more power.

-

For a 65-inch TV, LED uses about 88 watts per hour. Oled uses around 116 watts per hour.

If you want to save energy, LED displays might be better. Oled displays give you better colors and contrast. But they can use more electricity.

OLED vs. Other Technologies

New display types like MicroLED are starting to show up. MicroLED displays are very bright and last a long time. Oled displays are still the best for thin and bendy screens. MicroLED displays do not have burn-in problems. They last longer. Both give you great color and contrast. MicroLED displays cost more right now.

Here’s a table to show the main differences:

|

Feature |

OLED Displays |

MicroLED Displays |

|---|---|---|

|

Contrast Ratio |

Excellent, true blacks |

High, true blacks |

|

Color Reproduction |

Vibrant, wide gamut |

Excellent, wide gamut |

|

Brightness |

Good |

Higher |

|

Lifespan |

Shorter |

Longer |

|

Burn-in |

Possible |

Rare |

|

Flexibility |

Thin, bendy designs |

Less flexible |

|

Cost |

Lower |

Higher |

You might pick oled displays for foldable phones or thin TVs. MicroLED displays work better outside and last longer. But you pay more for them.

Tip: If you want the best picture and a cool design, oled displays are a great choice. For saving energy and longer life, LED or MicroLED displays might be better for you.

OLED Buying Tips for Consumers

Best Uses for OLED Displays

You may wonder where OLED displays work best. These screens are great for some devices and situations. Look at this table to see where OLED displays give you the most benefits:

|

Use Case |

Advantages |

|---|---|

|

Televisions |

Amazing picture, deep blacks, bright colors, wide angles. |

|

Mobile Devices |

Sharp images, great colors, uses less power. |

|

Wearables |

Saves power, thin, bends easily, good for curved screens. |

|

Virtual Reality |

Fast refresh, quick response, deep blacks for real feel. |

|

Automotive |

Bright screen, wide angles, saves energy, custom shapes. |

|

Lighting |

Soft light, colors and brightness can be changed. |

If you enjoy watching movies or playing games, OLED screens are a smart choice. You also find them in smartwatches and car dashboards.

Who Should Buy OLED

Not everyone needs an OLED screen. Think about what is most important to you. Here are some things to think about:

-

Picture quality: OLED screens show strong contrast and bright colors.

-

Design flexibility: Devices with OLED screens are thin and light.

-

Energy efficiency: OLEDs save power with dark images, but use more with bright ones.

-

Burn-in issues: If you keep one image on the screen, you may see marks later.

-

Cost: OLED screens usually cost more than other types.

-

Compare with other screens: Mini-LED or QLED are other choices.

If you want the best picture and a slim device, OLED screens are a good pick. If you care more about price or need a screen for long, heavy use, you may want something else.

Preventing Burn-In

You can keep your OLED screen looking good by following some easy tips:

-

Change what is on your screen often. Do not leave one image for hours.

-

Lower the brightness. High brightness wears out pixels faster.

-

Use dark mode when you can. This helps your screen last longer.

-

Turn on screen savers or use tools like Pixel Refresher.

Tip: Take care of your OLED screen, and you will enjoy great pictures for years.

You have seen both the good and the bad of oled displays. These screens give you deep blacks, bright colors, and fast response times. Many people love the look and feel of an oled display. Here are some things you should think about:

-

Superior image quality with deep blacks and vibrant colors

-

Energy efficiency for longer battery life

-

Design flexibility for cool, thin devices

-

Fast response for smooth motion

Recent surveys show that most users feel happy with their oled displays:

|

Metric |

Value |

|---|---|

|

Satisfaction Rate |

90% |

|

New Models with Smart Features |

80% |

If you want the best picture and a modern design, oled display modules are a great pick. Think about how you use your devices and what matters most to you before you buy.