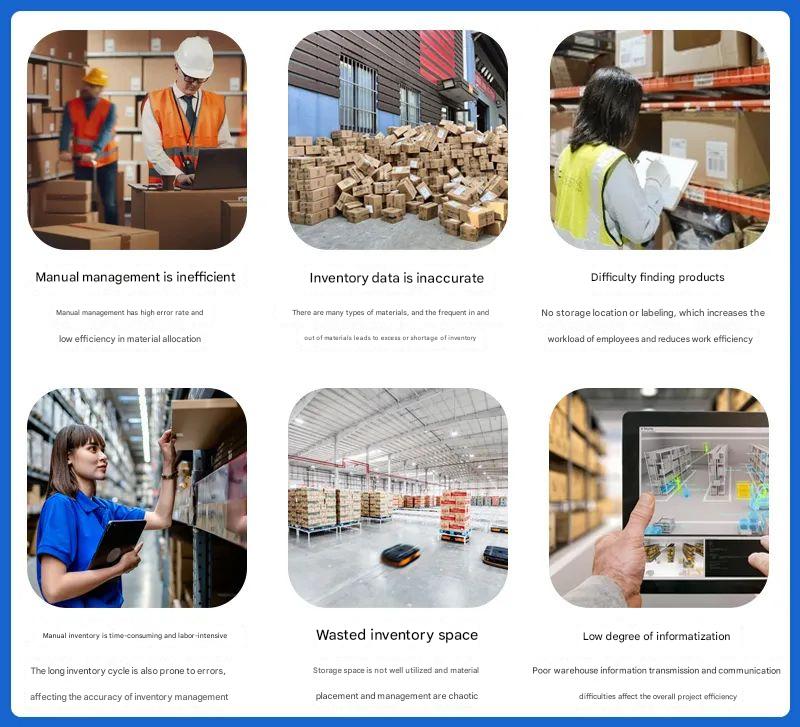

How can logistics PDA realize smart logistics and smart express?

PDA

Handheld scanner gun is a kind of handheld PDA, which is called Ba gun in logistics enterprises. Express company wireless scanning gun in the development trend of intelligent logistics has been widely used, its technical with automatic retrieval technology, wireless communication technology and database system integration integration, is the key development prospects of intelligent logistics information content fully automatic access and instant transmission.

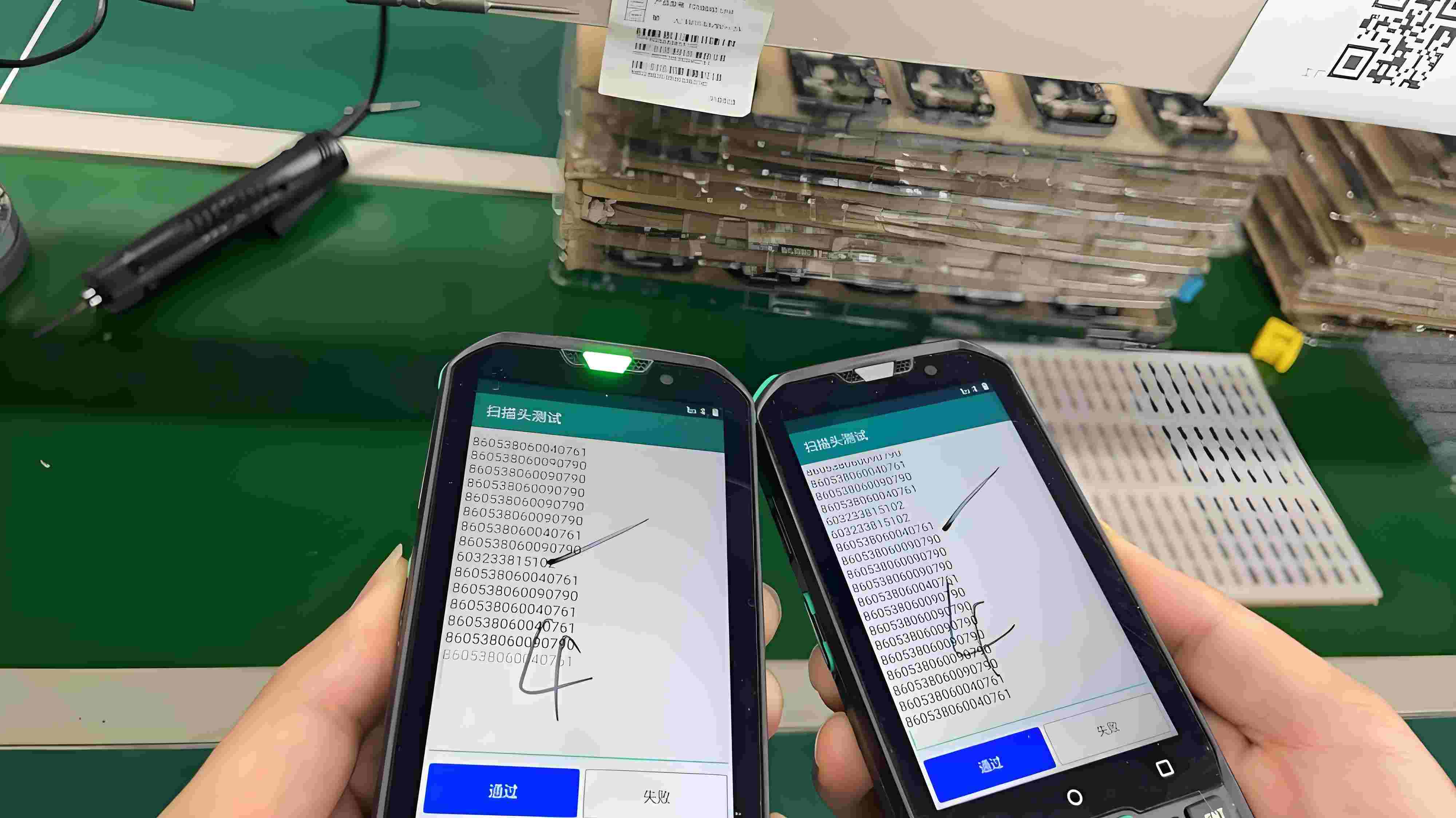

Rapid verification of data files

It is adjusted to the electronic computer document, and the scanning gun is applied to carry out the total number of goods to confirm, the type to confirm, to confirm immediately, and to carry out the checking of the bar code. Here according to the handheld PDA operation immediately change and confirm the backstage management data files, not only saves the backstage management electronic computer personnel into the entry and verification of the repeated whole process of documents, reducing the obligation stage, but also not easy due to the entry of incorrect and incorrect stock of the originality of the incorrect, to enhance the warehouse personnel's obligations and rights.

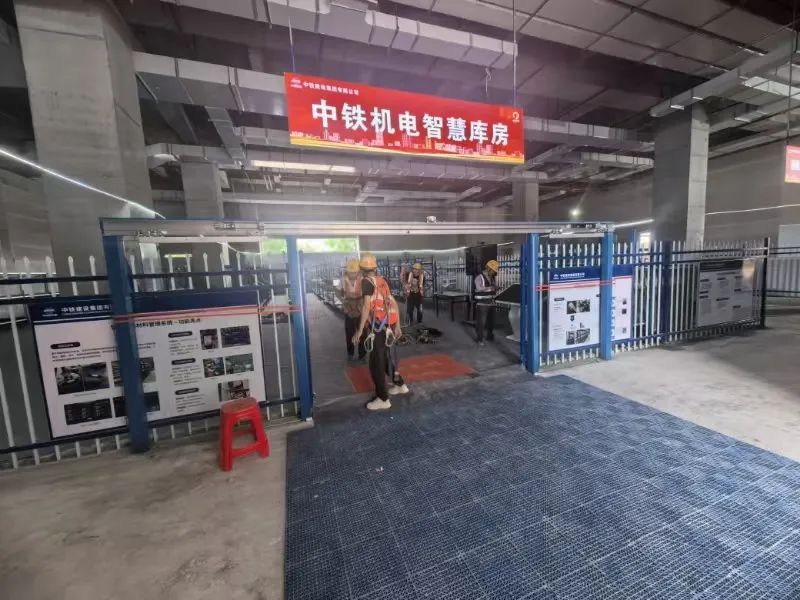

Precise location of cargo

Accurately locate and place goods according to handheld PDA device markings. Enhance the utilization rate of the cargo space and the overall efficiency of its warehouse management. After the warehouse manager clearly puts forward the order to place, the system software automatically reminds the indoor space where the goods must be placed and the characteristics of the warehouse shelves, and even can immediately deliver the goods to the delivery area according to the order, which improves the high efficiency.

Efficient recording of logistics details

Handheld PDAs enable immediate access to logistical details of the operational record relationship, such as delivery company arrival times, high efficiency, and characteristics of operating personnel and machinery and equipment.

Aggregation/verification of documentation information

Handheld PDA has a separate product immediately to carry out a separate summary, accurate verification, immediate verification, to complete the summary of the role of a one-time. Prevent incorrect and delayed time because of the entry of documents, and its because of different personnel, different time, different methods, different situations of verification itself appears wrong, in addition to reducing the cost of copying a lot of documents produced by the cost of depletion.

- end -