How to Reduce Labor Costs and Minimize Human Errors in Warehouse Operations Using Industrial AIDC Solutions

From Cost Center to Data Hub: Revolutionizing Warehouses with AIDC in 2026

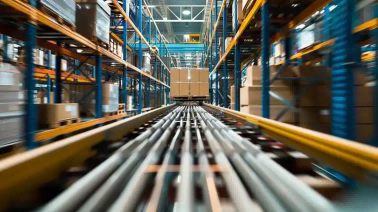

Summary: Warehouse operations are no longer just about storage and shipping; they've become a strategic, data-driven asset central to customer experience and business resilience. By integrating modern Automatic Identification and Data Capture (AIDC) technologies, businesses can systematically address the dual challenges of high labor costs and operational errors, moving beyond incremental fixes to achieve transformative efficiency.

The Modern Warehouse: A Strategic Pivot Point

Today’s distribution center is a critical hub. It’s no longer a passive cost center but a dynamic data engine and often the final physical touchpoint with the customer. In 2026, leadership that relies on intuition alone is unsustainable; data-driven decision-making has become a matter of survival for warehouse operations.

Decoding AIDC: Beyond Simple Barcode Scanners

AIDC is a comprehensive ecosystem of technologies designed to automatically identify objects, collect data, and feed it directly into management systems without manual entry. While barcodes are foundational, the modern AIDC toolkit in 2026 includes:

1. Radio-Frequency Identification (RFID): Enables bulk reading and real-time tracking without direct line of sight. UHF RFID tag costs have fallen significantly, driving annual global consumption to over 80 billion units.

2. AI-Powered Vision Systems: Use cameras and deep learning for complex recognition tasks, such as verifying mixed-SKU pallets or identifying damaged goods, with error rates as low as 0.03% in controlled industrial settings.

3. Mobile Computing & IoT Sensors: Handheld computers and environmental sensors provide workers with real-time data and enable constant monitoring of conditions like temperature and humidity.

A Step-by-Step Guide to Implementation

Transitioning to a smart warehouse is a strategic process. Here’s a practical guide for 2026:

1. Assess & Identify Pain Points: Conduct a thorough audit of your current infrastructure and processes. Pinpoint where delays, errors, and costs are highest, such as receiving, picking, or cycle counting.

2. Start with a Focused Pilot: Choose one high-impact area for a technology pilot. Implementing IoT sensors for real-time inventory tracking or handheld computers for guided picking in a specific zone can demonstrate quick ROI and build internal support.

3. Integrate Systems Deeply: Ensure your new AIDC tools are fully integrated with your core Warehouse Management System (WMS) and Enterprise Resource Planning (ERP) software. Disconnected systems are a major competitive disadvantage.

4. Train and Empower Your Team: Invest in change management. Train employees to work with new technology, focusing on how it makes their jobs easier and more valuable, such as by reducing tedious manual searches.

5. Scale and Optimize: Based on pilot results, develop a phased rollout plan. Use collected data to continuously refine processes, explore advanced automation like Autonomous Mobile Robots (AMRs) for material handling, and expand visibility across the supply chain.

The Tangible Benefits: From Labor to Leadership

The impact of a well-executed AIDC strategy is measurable across multiple dimensions:

| Benefit Category | Key Outcomes & Metrics |

| Labor Productivity & Cost | Reduces walking time by 30-50% with optimized pick paths. Cuts labor costs by up to 40% and manual audits by 80%. |

| Operational Accuracy | Achieves 99.9%+ picking and shipping accuracy. Enables real-time, 24/7 inventory visibility with 99%+ stock accuracy. |

| Strategic Decision-Making | Provides data for AI-driven demand forecasting (up to 95% accuracy), dynamic slotting, and predictive analytics, transforming the warehouse into a profit driver. |

The Future-Proof Warehouse: Trends for 2026 and Beyond

To stay competitive, look beyond immediate tools to these converging trends:

1. AI as an Operational Tool: AI is moving from hype to practical application in labor forecasting, dynamic slotting, and anomaly detection, acting as a core utility within the warehouse "toolbox".

2. Automation with Purpose: The trend is shifting from automating everything to "automating the constraint"—intelligently deploying AMRs and cobots where they deliver the clearest ROI.

3. End-to-End Ecosystem Visibility: True transparency from supplier to customer is becoming non-negotiable. Technologies like blockchain are being explored to create immutable audit trails and enhance supply chain provenance.

4. Sustainability as an Operational Metric: Green practices are evolving from marketing to core operational goals, influencing decisions on packaging, energy use, and network design to meet rising regulatory and customer expectations.

Conclusion: The Journey to a Smarter Hub Begins Now

Transforming your warehouse with AIDC is a strategic journey that aligns technology with process and people. The goal is to build an operation that is not only more efficient and accurate but also more agile, resilient, and strategically valuable. In 2026, the winners will be those who leverage data and automation not to replace human judgment, but to empower it, creating a warehouse that is truly a strategic asset for the business.

To further explore how specific AIDC technologies like RFID or AI vision systems can be tailored to your industry's unique challenges, feel free to ask for a deeper dive into any of these solutions.

-----------------------------------------