How to Choose the Right Monochrome LCD Display for Your Project

How to Choose the Right Monochrome LCD Display for Your Project

You should match the features of your monochrome lcd display to what your project needs. Picking the right one makes your project easier to use. It also makes it more reliable. Many fields like healthcare and industrial automation use mono lcd display technology. This is because it gives strong contrast and lasts a long time. These displays show clear and steady information. They work well even in tough places. If you pick the right lcd display, you save money. You also use less power. Choosing the best mono lcd display helps your project do well for a long time.

Key Takeaways

-

Make sure the monochrome LCD display has features your project needs. This helps make it easier to use and more reliable. - Think about the display's size, resolution, and if it works with your device. This makes sure it fits your system. - Look at how bright the display is, its contrast, and the angle you can see it from. This helps you see the screen well in different lights. - Check how much power the display uses. This is important if you want your battery to last longer, especially for things you carry. - Pick a display that can work with new technology later. This helps you upgrade your project in the future.

Project Needs for Choosing Mono LCD Displays

Application and Physical Constraints

When you start choosing mono lcd displays, you need to think about what your project will do. Many devices use these screens because they show clear information without color. You often see them in:

-

Digital watches

-

Calculators

-

Industrial control systems

-

E-readers

-

Medical equipment

-

Consumer electronics

You should ask yourself what kind of information your project needs to show. If your project only needs simple numbers or text, a monochrome lcd display works well. You also need to look at the size of your device. Some projects have very little space for a screen. Others need a bigger display so users can read it from far away.

Tip: Measure the space where you want to put the display before you buy anything. This helps you avoid problems later.

Budget and Use Environment

Cost and budget constraints play a big role in choosing mono lcd displays. If you want a custom screen, you may pay between $4,500 and $6,500 for tooling. For custom glass, the price usually falls between $2,000 and $2,500. You should plan your budget early so you do not run into surprises.

The environment where you use your mono lcd display matters a lot. High heat or cold can damage the screen. Humidity can also cause problems inside the display. If your project will be outside or in a factory, you need a screen that can handle tough conditions. Extreme temperatures and moisture can make the display age faster and show errors.

Note: Always check the temperature and humidity ratings before you choose a display. This helps your project last longer and work better.

When you match your display to your project’s needs, you get better results. You also avoid wasting money and time. The monochrome lcd display market offers many choices, so take your time and pick the best one for your use.

Monochrome LCD Display Selection Criteria

When you pick a mono lcd display, you need to think about a few important things. Each thing changes how well your display works in your project. You want your display to be easy to see, use little energy, and work well.

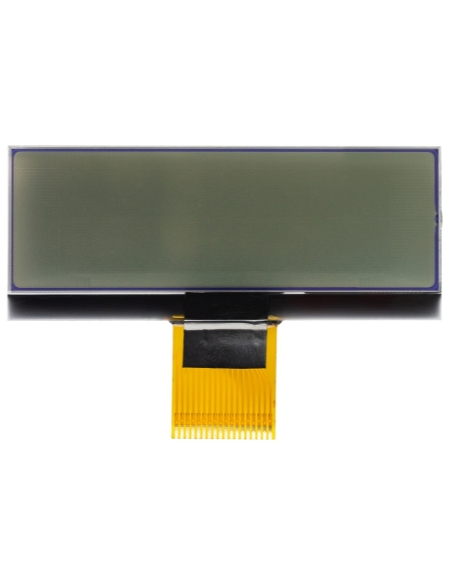

Size and Resolution

Size and resolution matter a lot for any mono lcd display. You should choose a display that fits your device. It must show information clearly. There are many choices for size and resolution in the market.

Here is a table with common options:

|

Resolution Options |

Size Options |

|---|---|

|

8 ~ 40 Characters |

1 ~ 4 Lines |

|

24×24 ~ 320×240 Pixels |

Various column and row formats |

The sharpness of images and text depends on the resolution. More pixels in the same space make things look clear and smooth. Fewer pixels can make things look blurry or blocky.

If you pick a higher resolution, you get clearer text and images. This makes it easier for people to read the screen. It also helps in bright light. For example, smartwatches need high resolution so people can see the screen outside.

-

Higher resolution gives sharper and clearer text and images.

-

Less eye strain makes it easier to use.

-

Good readability works in different lighting.

Always match the size and resolution to your project’s needs. This helps you pick the best mono lcd display.

Interface Compatibility (SPI, I2C, etc.)

Interface compatibility is another important thing to check. You need to see if the display works with your controller board. Common interfaces are SPI and I2C. If your display matches your system, you save time and money. If it does not match, you may need extra parts or changes, which costs more.

Always check compatibility before you buy. This helps you avoid problems and makes picking a mono lcd display easier.

Brightness, Contrast, and Viewing Angle

Brightness and contrast help you see the display better. You want your mono lcd display to look good in all kinds of light. Outdoor projects need higher contrast for better reading.

|

Contrast Ratio |

Readability Level |

|---|---|

|

5 |

Acceptable |

|

10 |

Well readable |

|

15 |

Outstanding |

|

20 |

Excellent |

Viewing angle matters too. Some displays look clear only from certain angles. Others let more people see the screen at once.

-

If your project needs a wider viewing angle, there are choices.

-

You pick based on cost or what is available.

-

The right viewing angle helps your display work best.

-

Narrow angles are good for one person.

-

Wide angles are better for sharing.

-

Matching the angle to the user helps with clarity and use.

Always think about brightness, contrast, and viewing angle when you pick a mono lcd display. These things help you get the best look and use.

Power Efficiency

Power efficiency is very important for portable devices. Mono lcd displays use less energy than color screens. This means your device’s battery lasts longer.

-

Medical devices like blood analyzers and portable tools use mono lcd displays because they save power. This helps batteries last longer.

-

Digital cameras and smart thermostats use mono lcd displays for their screens. Low power use means longer battery life and better user experience.

Always look for good power efficiency and low power use when you pick a mono lcd display. This helps your device run longer and saves energy.

If you follow these important steps, you make a smart choice for your project. You get good visibility, compatibility, and efficiency. Your mono lcd display will help your project do well.

Reliability and Environmental Resistance in Mono LCD Displays

Durability and Longevity

You want your display to last for years. It should work well every day. Companies test mono lcd displays in many ways. These tests show if the screen can handle drops and scratches. They also check if sunlight will hurt the display. Here is a table that shows how companies test durability and longevity:

|

Testing Method |

Description |

|---|---|

|

UV Durability Testing |

Uses special lights to copy sunlight and see how the display reacts over time. |

|

Temperature/Power Cycling |

Checks if the display works when temperatures and power levels change quickly. |

|

Scratch Resistance Testing |

Tests how well the display stands up to scratches from sharp objects. |

|

Mechanical Stress Tests |

Pushes and bends the display to see if it breaks or cracks. |

|

Humidity and Water Spray Test |

Sprays water and adds moisture to see if the display keeps working in wet conditions. |

These tests help make sure your display is tough. If you use your display in a factory or outside, you need it to be reliable.

Temperature and Humidity Tolerance

You should check if your display works in hot or cold places. Some mono lcd screen models have different temperature ratings. The table below shows common ranges:

|

Type of LCD Display |

Temperature Range |

|---|---|

|

Standard Industrial-Grade |

-20°C to 70°C |

|

Consumer Displays |

0°C to 50°C |

|

Extended Models |

-30°C to 85°C |

|

Specialized Variants |

-40°C to 110°C |

Displays with bigger ranges work better in extreme weather. Humidity can also change how well your display works. Industrial displays are made to handle dust and moisture. You can use them in cars or factories. These screens use advanced technology and last a long time. They work well even in tough places.

-

Industrial displays work in places with dust and moisture.

-

They last longer and keep showing clear information.

-

You can trust them for important jobs where reliability matters.

Tip: Always check the temperature and humidity ratings before you choose a display. This helps your project stay safe and reliable.

Integration and Guidelines for Effective Mono LCD Product Selection

System Integration

You need your mono lcd display to work with your system. This is called integration. If you use a microcontroller, check if the display fits your board. Look at the interface and voltage. Picking SPI or I2C helps your project run well. You must match the voltage and timing. If you do not, the display may flicker or break.

Here is a table with common problems you might see:

|

Challenge |

Explanation |

|---|---|

|

Interface Selection |

Pick the right interface for your display and microcontroller pins. |

|

Voltage-Level & Timing Matching |

Make sure voltage and clock speeds are the same. Sometimes you need level shifters. |

|

Common Pitfalls |

Wrong clock speed can cause lag or flicker. Bad voltage can break your display. |

Tip: Test your timing and voltage early. This helps you find problems before they get worse.

You can change refresh rates to stop flickering or ghosting. If you follow these steps, your mono lcd display will work better.

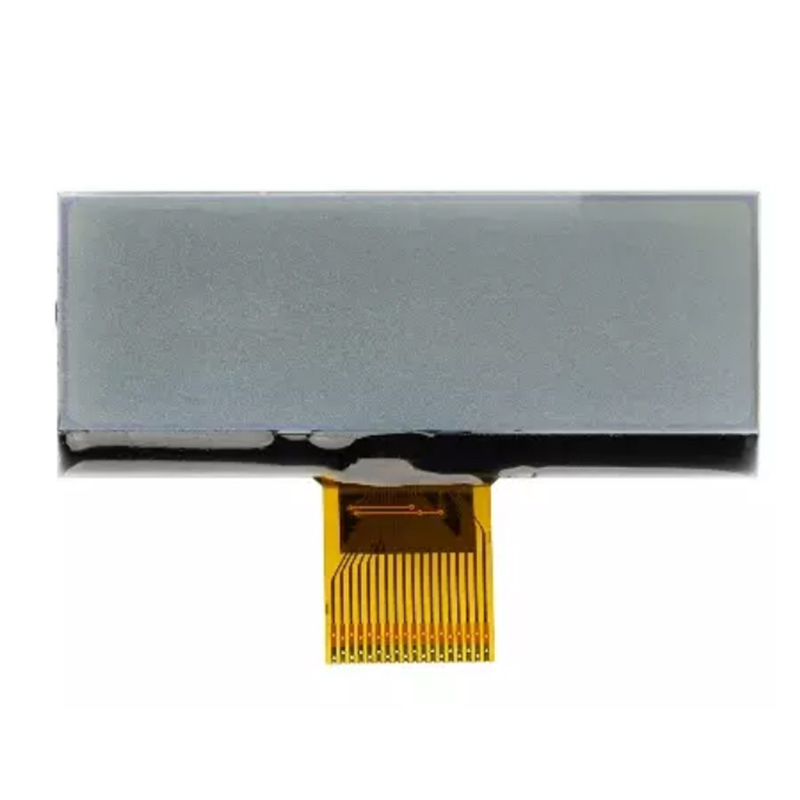

Customization Options

Some projects need special features. You can pick from many customization options for your display. Suppliers offer different screen sizes, viewing angles, and backlight colors. You can choose the interface type and temperature range. Some suppliers let you change the shape or add things like touchscreens.

Here is a table with common choices:

|

Feature |

Description |

|---|---|

|

Screen Size |

Sizes like 128x64 mm or 192x64 mm are popular. |

|

Viewing Angle |

Wide angles, up to 160 degrees, help more people see the display. |

|

Backlight Options |

Colors like Yellow, Green, Blue, and others. |

|

Interface Types |

Choices include I2C, SPI, and Parallel. |

|

Temperature Range |

Works in places from -20°C to 70°C. |

|

Custom Solutions |

You can ask for special shapes or features for your project. |

You can also get custom cables, connectors, PCB changes, or optical bonding for stronger screens. Some suppliers offer TN, STN, or VATN displays. These change the contrast and brightness. You can pick what works best for you.

Customization helps your project grow. If you need to make more, you can change the size or resolution. This makes your mono lcd display flexible for new uses.

|

Feature |

Impact on Scalability |

|---|---|

|

Size Customization |

Fits your display to your project, so it works in many industries. |

|

Resolution Customization |

Lets you meet exact needs, so you can use the display in different systems. |

Note: When you plan ahead, pick a display you can change or upgrade as your project grows.

Supplier Support and Service

Good supplier support helps your project do well. Look for suppliers who give technical help and testing. Many suppliers let you test samples to check how the display works, how strong it is, and how much power it uses. They also check factories to make sure displays are made well. Some suppliers show where they get their parts, so you know you can get more displays when you need them.

Here is a table that shows good supplier service:

|

Evidence Type |

Description |

|---|---|

|

Sample Testing |

Checks how the display works, how long it lasts, and how much power it uses. |

|

Factory Audits |

Makes sure the displays are made with good quality. |

|

Supply Chain Transparency |

Shows where the parts come from and helps you get displays when you need them. |

You can find suppliers with many display types, like graphic LCDs, character LCDs, and VATN LCDs. They may offer different backlight colors, like blue, green, or amber. Some let you pick RGB LED backlights or low-power options.

Tip: Pick a supplier who helps you set up and answers questions fast. Good support makes fixing problems easier and keeps your project running.

If you follow these guidelines, your project gets stronger. It is easier to fix problems and grow later. Good integration, smart customization, and strong supplier support help you get the most from your monochrome lcd display.

Future Trends and How to Choose the Right LCD Display

Technology Advancements

Every year, new things happen in the monochrome lcd display market. Companies work hard to make displays use less energy. They want screens to last longer and work better everywhere. Healthcare, cars, and electronics need displays that are reliable and cheap. Makers use new ways to build displays so they are stronger and clearer. These changes help you pick a display that fits your project and saves power.

-

Saving energy is very important for new displays.

-

Building methods keep improving each year.

-

Many businesses want displays that work well and cost less.

-

You can find more strong and clear screens now.

If you learn about these changes, you can choose the best mono lcd display for your project.

Planning for Upgrades

You should think about what you might need later when you pick a mono lcd display. Planning for upgrades helps your project last longer and work better. You want a display that can grow with your system and follow new rules. Some displays have new things like better contrast or ways to connect to smart devices.

|

Factor |

Description |

|---|---|

|

Scalability |

Can the display support future upgrades or work with new systems? |

|

Regulatory Compliance |

Does it meet today’s safety and environmental rules? |

|

Innovation |

Are there features like better contrast, new connections, or IoT options? |

|

Long-term ROI |

What are the savings, durability, and costs over time? |

Monochrome LCD displays last longer than color screens. You do not need to change them as often. Color displays can lose quality faster because of burn-in or fading. You save money and time by picking a display that stays strong for years.

Tip: Always check if your display can handle new features or rules before you buy. This helps your project stay ready for the future.

You can pick the best monochrome lcd display if you follow easy steps. First, decide what your display will show. Measure the space for your screen. Check your controller to see what works with it. Pick the right interface for your project. Make sure the resolution and size fit your needs. Always check the voltage, backlight, and connector type. Learn about new things like mini-LED backlighting. Look at hybrid display strategies too. This helps your mono lcd display work well for a long time.

Checklist for Final Decision:

-

Decide what your display needs and size are.

-

Make sure your controller works with the display.

-

Pick the right interface for your system.

-

Match the resolution and size to your project.

-

Check voltage, backlight, and connector type.

-

Think about upgrades and new trends for the future.

Learning about new technology helps your project stay strong and ahead.