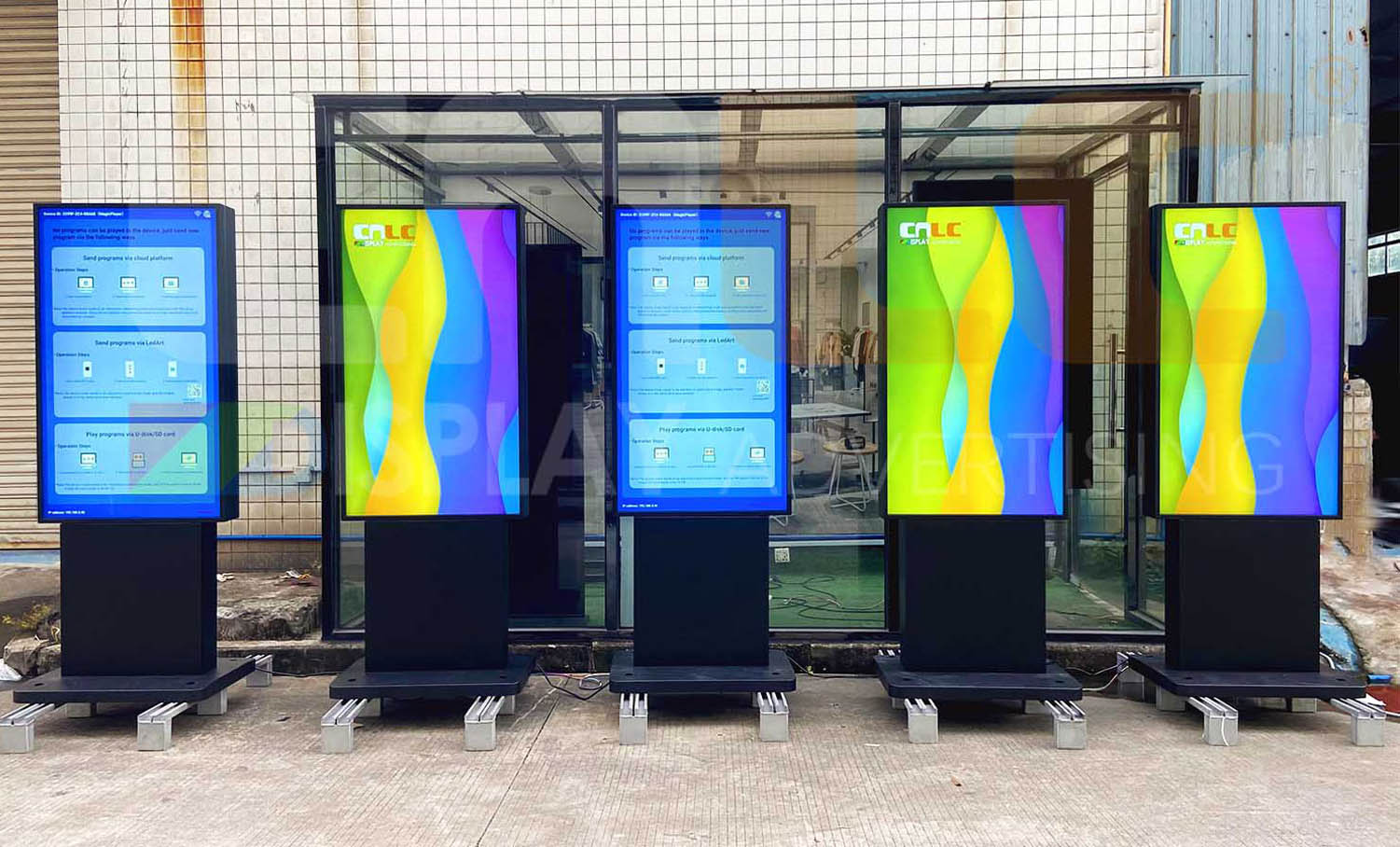

CNLC at ISE 2025 Elevating Outdoor Digital Signage with Innovation

The Integrated Systems Europe (ISE) 2025 is in full swing, and CNLC is proud to be part of this global event, showcasing our latest LED & LCD digital signage solutions. As a leader in outdoor digital advertising displays, CNLC continues to push the boundaries of innovation, delivering high-brightness, durable, and energy-efficient signage solutions for various industries.

Whether you’re looking for weather-resistant LED billboards, smart city digital displays, or high-impact retail signage, CNLC is here to transform your digital advertising strategy.

Why CNLC’s Digital Signage Stands Out at ISE 2025

At ISE 2025, Hall 5 - 5R550, CNLC is unveiling its latest advancements in aluminum-structured digital signage. Our industry-leading displays are designed to perform in challenging outdoor environments, ensuring high visibility, durability, and efficiency.

Key Features of CNLC’s Digital Signage Solutions:

✅ High-brightness LED & LCD displays for enhanced visibility in all lighting conditions

✅ Aluminum-structured enclosures for superior durability and heat dissipation

✅ IP-rated weatherproof designs to withstand rain, dust, and extreme temperatures

✅ Energy-efficient technology, reducing operational costs

✅ Smart connectivity options, including remote content management and interactive displays

✅ SKD (Semi-Knocked Down) design for flexible assembly and cost-effective shipping

Our team has been actively engaging with industry professionals, discussing how digital signage is shaping the future of advertising, smart cities, and public information systems.

Experience CNLC’s Latest Digital Signage Innovations

ISE is the ultimate platform to explore cutting-edge display technology. If you haven’t visited us yet, there’s still time to experience our high-performance LED & LCD solutions at Hall 5 - 5R550. Our expert team is ready to provide live demonstrations, answer your questions, and discuss customized digital signage solutions for your business.

? Watch Our ISE 2025 Highlights!

Couldn’t make it to the event? Don’t worry! We’ve captured all the action—watch our event highlights video to see our digital signage solutions in action and hear from our team of experts.

Let’s Stay Connected!

ISE 2025 may be coming to an end, but our commitment to revolutionizing digital signage continues. If you’re looking for customized LED & LCD display solutions for your business, get in touch with CNLC today!

? Contact us for product inquiries and partnerships: Click Here

? Explore our full product range: Visit Our Website

? Join us at ISE 2025, Hall 5 - 5R550, and discover the future of digital signage!

About CNLC

With over 18 years of experience, CNLC is a trusted OEM/ODM manufacturer of outdoor digital signage solutions. Our high-brightness LED & LCD displays are widely used in smart cities, transportation hubs, retail, and outdoor advertising. We are committed to quality, innovation, and sustainability, helping businesses worldwide enhance their digital advertising strategies.