RFID and UHF RFID Explained — A Complete Guide for Logistics, Warehousing, and Asset Management

Introduction: When Traditional Management Meets Technological Limits

In traditional logistics and warehouse management, have you ever faced these situations?

Warehouse stocktaking requiring all-hands overtime, frequent missed or incorrect scans during manual barcode reading, spending hours locating a critical piece of equipment… These pain points silently erode organizational efficiency and profitability.

The emergence of RFID technology is quietly rewriting the rules of the game.

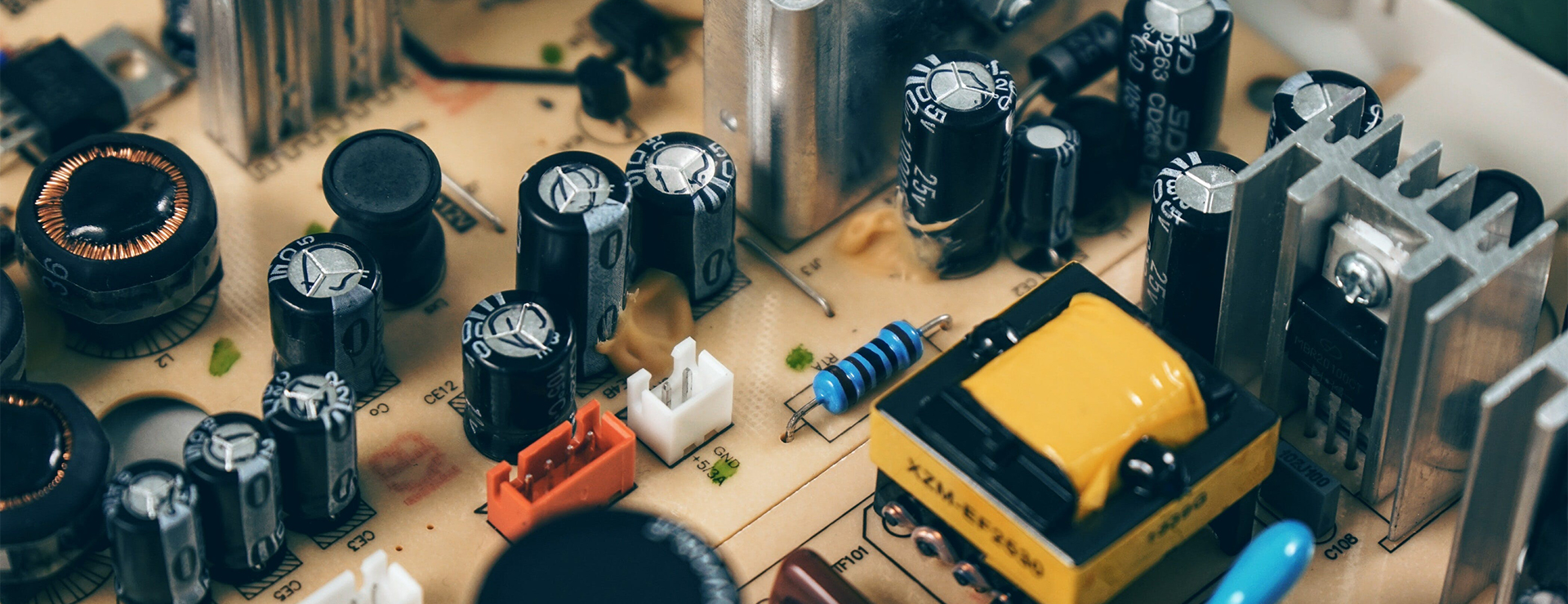

RFID Fundamentals — More Than Just an “Advanced Barcode”

1.1 What is RFID?

RFID (Radio Frequency Identification) is a technology that uses radio waves to automatically identify objects and capture related data. Unlike barcodes that require direct line-of-sight, RFID tags can be read from several meters away without visual contact.

1.2 The Three Core Components:

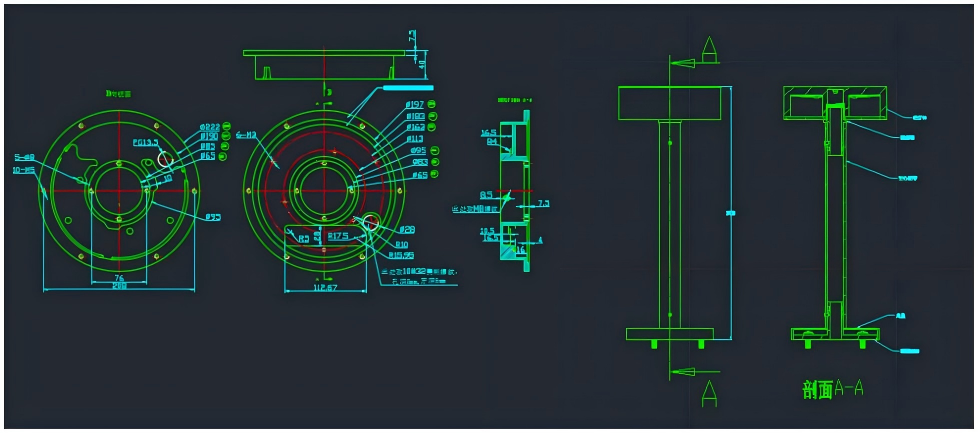

RFID Tags: Microchips integrated with an antenna, attached to items

RFID Readers: Devices that transmit and receive radio signals to communicate with tags

Backend System: Software that processes, analyzes, and stores the captured data

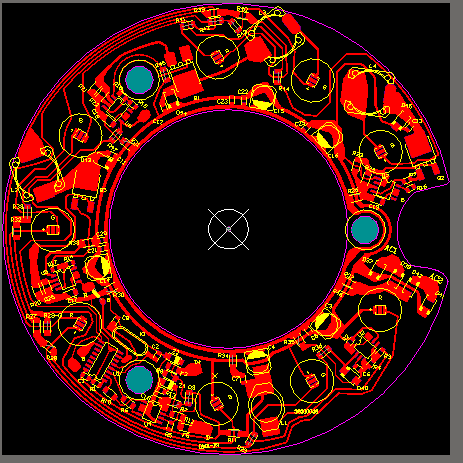

UHF RFID — The Game Changer for Logistics and Warehousing

2.1 Key Advantages of UHF RFID

Operating in the 860–960 MHz frequency range, Ultra-High Frequency (UHF) RFID offers:

Longer read ranges — up to 10–15 meters

Bulk reading capability — hundreds of tags simultaneously

High-speed reading — 1,000+ tags per second

Better penetration — can read through non-metallic materials

2.2 Technology Comparison

| Parameter | Low-Frequency RFID | High-Frequency RFID | UHF RFID |

|---|---|---|---|

| Frequency Range | 125–134 kHz | 13.56 MHz | 860–960 MHz |

| Read Range | < 0.5 m | < 1.5 m | 1–15 m |

| Read Speed | Slow | Moderate | Very Fast (bulk read) |

| Interference Resistance | High | Moderate | Sensitive to metals/liquids |

| Typical Applications | Access control, animal tracking | Libraries, payment cards | Logistics, warehousing, retail |

The RFID Revolution in Logistics

3.1 End-to-End Visibility

From supplier to end-customer, every package, pallet, or container equipped with an RFID tag enables real-time tracking of:

In/out timestamps and responsible personnel

Transportation routes and transit points

Environmental conditions (with integrated sensors)

ETAs and exception alerts

3.2 Real-World Case: DHL

After deploying UHF RFID systems in its logistics centers, DHL achieved:

40% faster cargo processing

90% reduction in manual stocktake time

99.9% order accuracy

Annual savings of millions in operational costs

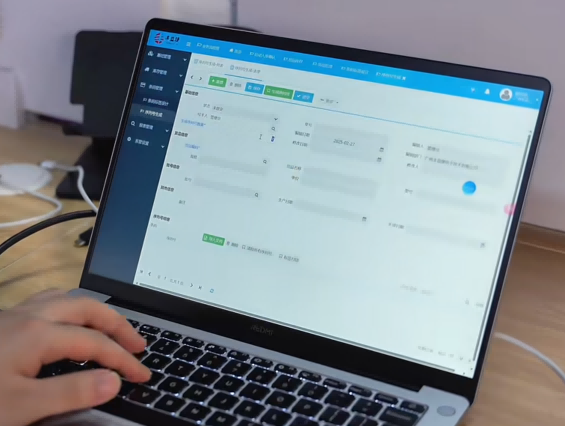

RFID Solutions for Smart Warehousing

4.1 Revolutionary Inventory Counting

Traditional manual count: 1 hour for 500 items

RFID count: 1,000 items in 1 minute

This leap in efficiency comes from RFID’s bulk-read capability. Staff simply walk through aisles with a handheld or vehicle-mounted reader, capturing data from hundreds of items in seconds.

4.2 Smart Shelving & Real-Time Inventory

RFID-enabled smart shelves can:

Automatically log item removal and replacement

Monitor stock levels in real time and trigger auto-replenishment

Prevent misplacement and optimize space utilization

Eliminate “lost stock” scenarios